|

In 1942 science-fiction writer Isaac Asimov published the first of the Foundation series stories in which he described a blaster that projected a beam so powerful it could slice steel as if it were butter. Not only does such a machine exist today, but there are thousands of them that cut steel plates into parts for other machines every hour of every day.

|

The laser took 50 years to make it from science fiction to science fact and today there are lasers that read movies from discs in your DVD player, lasers in supermarket price scanners, lasers used in surgery to correct eye problems, and lasers that transmit millions of gigabytes of Internet data worldwide over thousands of miles of optical fiber cables. Lasers are used to align machines, as rangefinders to measure distances, as cutting guides for power tools, and in computer printers. Lasers are one of thousands of examples of how physics touches your life.

|

Today, laser is a word found in the dictionary, but it was originally an acronym for Light Amplification by Stimulated Emission of Radiation coined in 1957. Lasers rely on quantum properties of certain types of atoms to absorb light of specific energy and hold it for a short time. By trapping these energized atoms between parallel mirrors, the light emission produced by one atom stimulates a matching emission from another atom, amplifying the original light. Bouncing back and forth between mirrors a trillion times per second, the pure light of a laser builds up almost instantly. A small hole in one mirror lets a fraction of the light out to make the beam.

|

The first lasers used crystals of pure ruby to make light. Today’s red, blue, and green visible-light lasers use semiconductors, similar to computer chips, to do the same thing at a very low cost. A low-power laser pointer can be bought at any office supply store for $10.

|

Researchers today might use a laser to align optical elements, to measure distances with fine precision, or to search for gravitational waves. Researchers at an observatory can use lasers to trace the Earth’s atmosphere, allowing astronomers to produce sharp images of stars and galaxies by removing distortions caused by the atmosphere. All of this has become possible because we have a deep understanding of the structure of the atom.

Researchers today might use a laser to align optical elements, to measure distances with fine precision, or to search for gravitational waves. Researchers at an observatory can use lasers to trace the Earth’s atmosphere, allowing astronomers to produce sharp images of stars and galaxies by removing distortions caused by the atmosphere. All of this has become possible because we have a deep understanding of the structure of the atom.

|

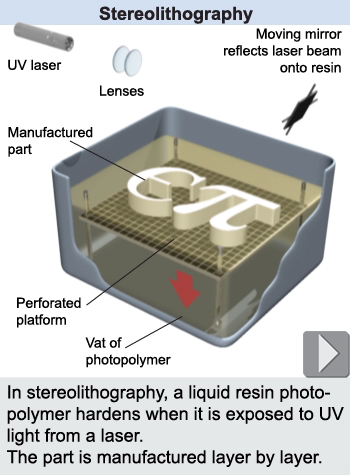

Another application of lasers is in producing parts using an additive manufacturing process called stereolithography. A stereolithograph apparatus (SLA) uses a liquid resin that cures or hardens when it is exposed to ultraviolet light. It “prints” layer by layer, from the bottom up, to produce the part. An ultraviolet laser shines on the surface of the resin to draw a cross-sectional layer of the part, causing the resin to harden wherever the laser is incident upon it. A perforated platform holding the part then lowers the part slightly and the UV laser shines at locations of the resin’s surface corresponding to the next cross-sectional layer of the part. The process repeats until every layer of the part is complete. The part is then cleaned and baked to harden it. Stereolithography can be used for rapid prototyping of designs, but it can also produce parts that are strong enough that they can be machined afterward as a step in the manufacturing process.

Another application of lasers is in producing parts using an additive manufacturing process called stereolithography. A stereolithograph apparatus (SLA) uses a liquid resin that cures or hardens when it is exposed to ultraviolet light. It “prints” layer by layer, from the bottom up, to produce the part. An ultraviolet laser shines on the surface of the resin to draw a cross-sectional layer of the part, causing the resin to harden wherever the laser is incident upon it. A perforated platform holding the part then lowers the part slightly and the UV laser shines at locations of the resin’s surface corresponding to the next cross-sectional layer of the part. The process repeats until every layer of the part is complete. The part is then cleaned and baked to harden it. Stereolithography can be used for rapid prototyping of designs, but it can also produce parts that are strong enough that they can be machined afterward as a step in the manufacturing process.

|

| |

|