|

Thermodynamics was developed to study systems in which heat energy is converted into other forms of energy such as mechanical or electrical energy. The prefix thermo refers to temperature and dynamic refers to motion. Thermodynamic systems are not “steady state” but instead involve temperature, pressure, or other variables changing dynamically over time. A good example is the internal combustion engine in a car. Designing an engine to get better efficiency—more miles per gallon—requires a thorough understanding of thermodynamics, the physics of thermal energy in motion.

|

The first real steam engine

|

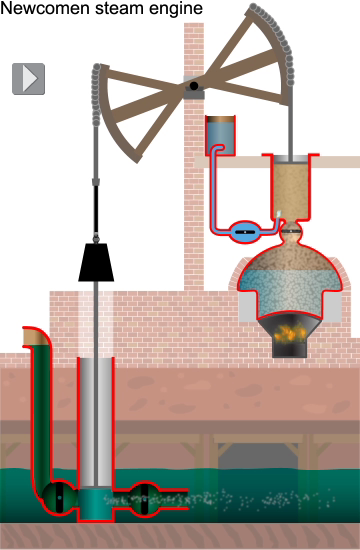

You could argue that the transition from the agricultural world of horse-drawn carriages to today’s mechanized world of automobiles and electric power stations began in 1712. That is when an English ironworker named Thomas Newcomen built the first working steam engine. Newcomen lived in an area where coal mining was a major occupation. Mines are essentially holes in the ground, which means that there is always a need to prevent flooding caused by the seepage of water into the mine. Newcomen’s engine operated the first commercially successful pump that used heat instead of animals for motive force.

|

|

To understand how Newcomen’s engine works, consider that a liter of liquid water expands to occupy 1,654 L of gas when it boils into steam. That same 1,654 L volume of steam contracts back to 1 L if it condenses back into liquid water again.

|

A cycle starts with the piston pulled up by the heavy mass attached to the end of a rocking beam. The steam valve opens and steam replaces air in the cylinder. The steam valve now closes and a jet of cold water sprays into the cylinder, condensing the steam back into liquid. This creates a partial vacuum in the cylinder and air pressure forces the piston down, lifting the heavy mass. When the piston gets to the bottom, the air valve opens and now the heavy mass pulls the rocking beam back down, lifting the piston back up and operating the water pump. This cycle repeats up to 12 times per minute. Newcomen and his partners built more than 700 of these machines at mines across England.

|