|

Humans began building structures long before we could write down equations to solve physics problems. The ideas in this chapter were developed by people trying to understand why some buildings and bridges fell down while others did not. There is a crucial point here: We design something to succeed by designing it not to fail. You must think about how something might fail in order to design it to be strong enough to succeed. When designing buildings, bridges, and other structures, engineers must ensure that their designs are strong enough not only for the expected loads of normal operation but also for the highest possible loads.

|

The design process

|

The process of designing and evaluating a structure follows a well-defined procedure.

The process of designing and evaluating a structure follows a well-defined procedure. - Envision a design concept that satisfies all the constraints, such how much weight the structure needs to support.

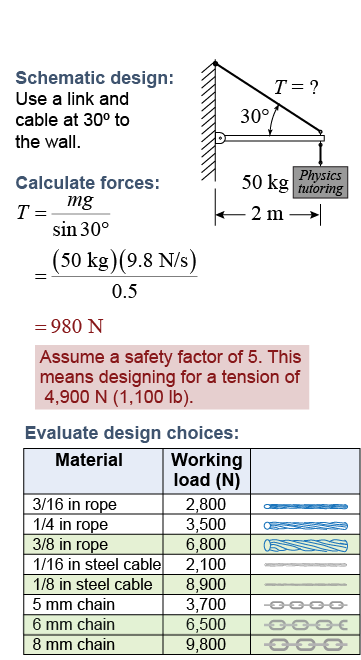

- Create a schematic design that provides details for the concept, such as length, height, angle, width, and materials used.

- Calculate the forces—using physics!—acting on each part of the structure under the design loads.

- Evaluate which design choice(s) can handle the calculated forces and meet other project requirements such as cost, weight, and environmental factors.

- Modify or refine the design based on these results, then go back to steps 3 and 4 to recalculate forces and reevaluate design choices, respectively.

- Keep repeating steps 3–5 until all parts of the structure are satisfactory.

Consider an example where a physics tutor wants to suspend a sign off the side of a building. After calculating the force exerted by the sign, she must evaluate different ropes, cables, and chains to determine which can support the load.

|

Engineers always apply a safety factor to all calculated forces when evaluating specifications of real materials. The safety factor helps account for the approximations of all force calculations, wear and tear, and variations in conditions, such as wind loads. When injury might result from failure, safety factors are often between 10 and 20. Note that four choices meet the required strength for the cable in the example: 3/8 in rope, 1/8 in steel cable, and the 6 mm and 8 mm chains.

|

| |

|