|

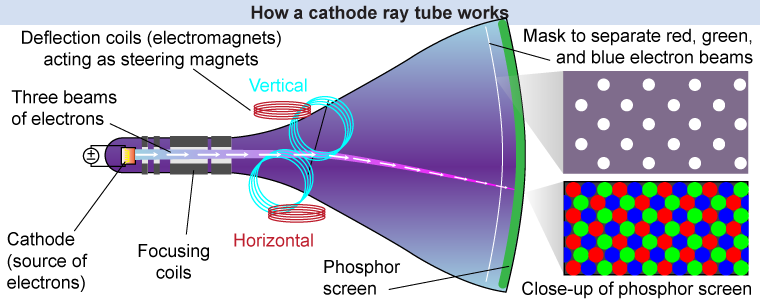

For many years television sets and monitors used a cathode ray tube (CRT) to project the image. Three beams of electrons (for red, green, and blue) are created and focused in the rear of the CRT. An incoming electrical signal passes through electromagnets that create a varying magnetic field that deflects and steers the electron beams to different locations on the screen. Three masks separate the three electron beams and then each causes a phosphor layer to fluoresce. The steering magnets vary rapidly to create 24 images per second on the screen.

|

|

You can see the connection between electricity and magnetism by using a strong magnet to deflect the electron beam inside a CRT. Watch the screen change while you move a horseshoe magnet around the screen of the CRT. Why does this happen?

|

Electromagnets are typically used when creating a strong magnetic field, but even copper wire has enough resistance to cause it to lose a lot of energy as heat. Some materials called superconductors have been found that exhibit no resistance at very low temperatures—whether at a few or tens of degrees above absolute zero. Superconducting magnets are electromagnets constructed from superconducting materials and they lose no energy as heat! Superconducting magnets are used to produce the strong magnetic fields in magnetic resonance imaging machines in hospitals, mass spectrometers, and particle accelerators, such as the Large Hadron Collider along the border of France and Switzerland.

|

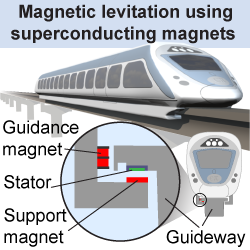

One application of superconducting magnets is to magnetically levitate high-speed trains. In the design illustrated at right, there are two sets of magnets. Magnetic attraction between the superconducting magnets of the undercarriage and the guideway lifts the “maglev” train above the track. Attraction and repulsion between magnets mounted on the side of the track maintain the horizontal alignment of the train. Magnetically levitating trains are currently in commercial use in China and Japan.

One application of superconducting magnets is to magnetically levitate high-speed trains. In the design illustrated at right, there are two sets of magnets. Magnetic attraction between the superconducting magnets of the undercarriage and the guideway lifts the “maglev” train above the track. Attraction and repulsion between magnets mounted on the side of the track maintain the horizontal alignment of the train. Magnetically levitating trains are currently in commercial use in China and Japan.

|

Research some of the advantages and disadvantages of maglev trains over conventional rail trains (including high-speed trains).

|

Examples of advantages include the following: Maglev trains experience no wear because there is no frictional contact between surfaces while they are in operation. Maintenance costs may be lower owing to lack of frictional contact. Disadvantages include the following: The construction costs for maglev trains are much higher than for conventional trains and the railways cannot have sharp turns. In addition, although maglev trains experience no rolling resistance, at high speeds the dominant friction is air resistance—which is common to all kinds of trains.

|